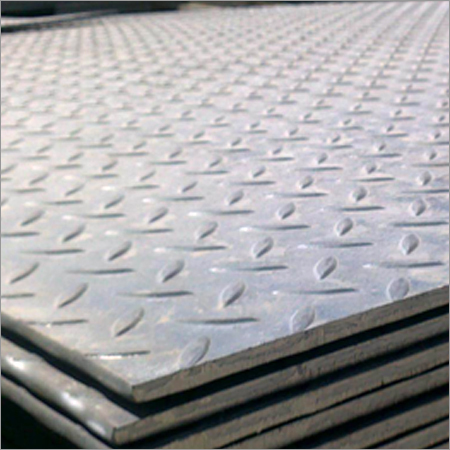

Chequered Plate

Chequered Plate Specification

- Alloy

- Mild Steel

- Usage

- Industrial, Construction

- Surface Treatment

- Hot Rolled

- Product Type

- Chequered Plate

- Grade

- IS 2062, ASTM A36

- Shape

- Rectangular

- Thickness

- 3 mm to 10 mm

- Length

- 2500 mm, 5000 mm, Custom

- Width

- 1250 mm, 1500 mm, Custom

- Application

- Flooring, Stair Treads, Ramps, Platform

- Color

- Silver

- Material

- Mild Steel / Carbon Steel

- Density

- 7.85 g/cm³

- Edge Condition

- Mill Edge / Cut Edge

- Form

- Sheet / Plate

- Corrosion Resistance

- Moderate (can be increased with galvanization)

- Finish

- Plain / Galvanized

- Tensile Strength

- Up to 410 MPa

- Pattern Type

- Diamond or Tear Drop

- Yield Strength

- 250 MPa minimum

- Standard

- IS 3502, ASTM A786

Chequered Plate Trade Information

- FOB Port

- KOLKATA

- Payment Terms

- Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- standard

- Main Domestic Market

- Nagaland, East India, Andaman and Nicobar Islands, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Jharkhand, Mizoram, Meghalaya, Manipur, Odisha, Sikkim, Tripura, West Bengal, Uttar Pradesh

About Chequered Plate

Owing to our expertise in the domain, we are involved in manufacturing and supplying an excellent array of Chequered Plate. This plate is manufactured by our highly experienced professionals in compliance with the set industry standards. Places where fall and slip easily occur, this plate helps eliminating the risk of accidents. Additionally, it can be used as a walk way platform due to its tolerance for heavy traffic areas. Further, it is well tested on various parameters to ensure its quality and flawlessness. We offer this, Chequered Plate in various specifications to cater the varied needs of the clients.

Features:

- Skid resistant

- Excellent tolerance

- Optimum strength

We are mainly dealing in West Bengal region.

Superior Strength and Durability

Designed to meet industrial standards, the chequered plate delivers high tensile and yield strengths, making it perfectly suited for applications where mechanical performance and safety are vital. Its robustness ensures longevity and reliability in high-traffic environments like construction flooring, ramps, and platforms.

Corrosion Resistance and Finish Options

Choose between plain or galvanized finishes to match your environmental demands. Galvanization significantly improves corrosion resistance, making these plates ideal for outdoor or moist conditions. The silver color and hot-rolled surface provide a modern aesthetic while maintaining practical performance.

Customizable Dimensions and Versatile Applications

With customizable thickness, length, and width, the chequered plate is available in standard sizes or tailored for specific project requirements. Its rectangular shape ensures easy installation for flooring, stair treads, and platforms, providing versatile solutions for both industrial and construction environments.

FAQs of Chequered Plate:

Q: How do I select the right chequered plate thickness and size for my project?

A: Assess your applications load requirements and available space. Chequered plates are available in thicknesses from 3 mm to 10 mm and standard widths (1250 mm, 1500 mm) and lengths (2500 mm, 5000 mm). For specific needs, custom sizes can also be supplied.Q: What is the process for manufacturing chequered plates with diamond or tear drop patterns?

A: Chequered plates are hot rolled from mild or carbon steel, then pressed to imprint either diamond or tear drop patterns. The process ensures consistent pattern depth and plate strength in line with IS 3502 or ASTM A786 standards.Q: Where are chequered plates commonly used in industrial and construction settings?

A: Chequered plates serve as flooring, stair treads, ramps, and platforms in factories, warehouses, and construction sites. Their slip-resistant patterns add safety and durability to high-traffic and heavy-load environments.Q: What benefits does galvanization offer for chequered plates?

A: Galvanized chequered plates have enhanced corrosion resistance, protecting them from rust and environmental degradation. This makes them suitable for outdoor or wet-area installation, thereby extending service life.Q: When should I opt for a mill edge versus a cut edge finish?

A: Mill edge plates retain the rolled edge for standard sizes, typically used where precise edge conditions arent critical. For custom projects or finishes, cut edge plates offer a cleaner, tailored edge, ensuring better fit and aesthetics.Q: How can the moderate corrosion resistance of mild steel be improved?

A: Opting for the galvanized finish increases the plates resistance to corrosion. The zinc layer acts as a barrier against moisture and chemicals, making the plate more suitable for harsh or outdoor environments.Q: What grades and standards are available for chequered plates supplied in India?

A: Chequered plates are available in grades like IS 2062 and ASTM A36, manufactured to international standards such as IS 3502 and ASTM A786. This guarantees quality and performance suited for demanding industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in MS Plate Category

MS Steel Plate

Minimum Order Quantity : on request Kilograms

Application : Construction, Manufacturing, Heavy Engineering

Color : Grey

Usage : Structural, Engineering, Fabrication

Shape : Other, Rectangular

Alloy : Mild Steel (MS)

MS Flat

Application : Automobile Industry, Construction

Color : Silver

Usage : Factory Materiel

Shape : Other, Rectangular

Alloy : With Alloy

GST : 19AAFFC5551M1Z3

|

CHANDI PRASAD AND SONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry