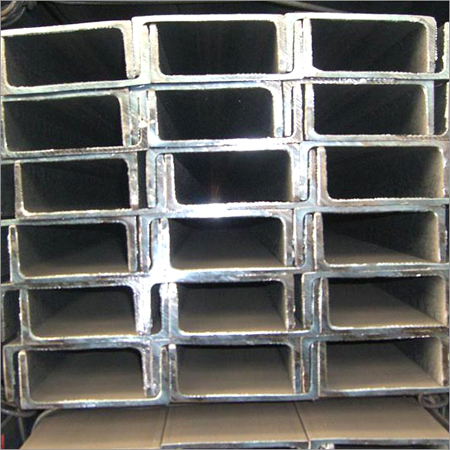

MS Channels

MS Channels Specification

- Usage

- Industrial, Construction, Structural Support

- Surface Treatment

- Hot Rolled

- Alloy

- Mild Steel (MS)

- Product Type

- MS Channel

- Grade

- IS 2062

- Shape

- C Channel

- Thickness

- 5 mm to 20 mm

- Length

- 6 meters to 12 meters

- Width

- 75 mm to 300 mm

- Application

- Building Frames, Bridges, Machinery

- Color

- Black, Grey

- Material Standard

- BIS Certified

- Delivery Condition

- As rolled

- Dimensional Tolerance

- As per IS:2062 and customer requirements

- Unit Weight

- 7.14 kg/m to 37.3 kg/m

- Manufacturing Process

- Hot Rolled

- Yield Strength

- 250 MPa minimum

- Tensile Strength

- 415 MPa minimum

- Flange Width

- 40 mm to 91 mm

- Edge Type

- Square Edge

- Corrosion Resistance

- Moderate (depends on surface treatment)

- Packing Type

- Bundle

MS Channels Trade Information

- FOB Port

- KOLKATA

- Payment Terms

- Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- Andaman and Nicobar Islands, Nagaland, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Himachal Pradesh, Jharkhand, Mizoram, Meghalaya, Manipur, Odisha, Sikkim, Tripura, West Bengal, Uttar Pradesh, East India

About MS Channels

We are passionately engaged in manufacturing and supplying an exceptional array of MS Channels. The channels find wide applications in several industries such as construction, automobile, steel plants and automotive. These are duly inspected to deliver a defect free range. Moreover, these are used for manufacturing of truck-trailers, tippers, generators frames, boilers, agricultural equipment, bus body, mechanized parking system, EOT cranes, ship building, factory sheds, conveyors, cable trays and construction of bridges. We offer these MS Channels in numerous specifications to meet the needs of our clients.

Features:

- Anti corrosive

- Precisely designed

- Excellent tensile strength

We are mainly dealing in West Bengal region.

Exceptional Strength and Reliability

Manufactured with a minimum tensile strength of 415 MPa and yield strength of 250 MPa, these MS Channels deliver outstanding load-bearing capability and structural integrity. Their BIS certification and adherence to IS 2062 standards guarantee superior reliability for demanding industrial and construction applications.

Versatile Dimensions for Multiple Uses

With flange widths ranging from 40 mm to 91 mm, thicknesses of 5 mm to 20 mm, and unit weights between 7.14 kg/m and 37.3 kg/m, these channels are available in black or grey finishes. Their C-channel shape and square edge make them suitable for building frames, machinery, bridges, and engineered structures.

Quality Manufacturing and Packing

These channels undergo a hot rolled process, ensuring durability and consistency. Packed in bundles, they are delivered in as rolled condition with strict dimensional tolerances as per IS:2062 and customer specifications, making them a trustworthy choice for traders and suppliers across India.

FAQs of MS Channels:

Q: How are MS Channels manufactured to ensure strength and durability?

A: MS Channels are produced using a hot rolled process with mild steel alloy, guaranteeing a minimum tensile strength of 415 MPa and yield strength of 250 MPa. This method imparts robust mechanical properties, ensuring each channel meets BIS and IS 2062 standards for industrial reliability.Q: What applications are MS Channels commonly used for?

A: These channels are widely employed in structural support roles, including building frames, machinery bases, bridges, and other civil construction projects. Their reliable strength and versatile dimensions make them suitable for a variety of industrial and construction contexts.Q: When should I consider surface treatment for corrosion resistance?

A: Although MS Channels provide moderate corrosion resistance in their hot rolled state, surface treatments such as painting or galvanizing are recommended for environments with high humidity or exposure to corrosive elements, increasing their lifespan and durability in challenging conditions.Q: Where are MS Channels typically supplied and used in India?

A: MS Channels are distributed by suppliers and traders throughout India and are a common choice for construction sites, industrial manufacturing facilities, and civil engineering projects requiring robust structural components.Q: What benefits do BIS certified MS Channels offer?

A: BIS certification assures users that the channels comply with stringent Indian quality standards, providing peace of mind regarding safety, mechanical strength, and consistency in construction and industrial projects.Q: How do dimensional tolerances impact the usage of MS Channels?

A: Dimensional tolerances, maintained as per IS:2062 and specific customer requirements, ensure that each channel fits precisely within engineered designs, reducing adjustment time and enhancing structural performance in final installations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

GST : 19AAFFC5551M1Z3

|

CHANDI PRASAD AND SONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry